Introduction:

The electrical grid is the backbone of modern society, ensuring that electricity reaches homes, businesses, and industry. However, the reliable and efficient operation of the grid is only possible through the proper maintenance of critical assets such as Gas Insulated Switchgear (GIS). The maintenance of GIS is complicated by common defects which cause partial discharge (PD) and in more severe cases complete flashovers or Arcs. These phenomena can cause equipment failure, unplanned outages, and safety hazards. To address these challenges, Qualitrol Corp. has developed innovative solutions that revolutionize Arc Detection and Localization.

What are “Arc Detection” and “Arc Localization”?

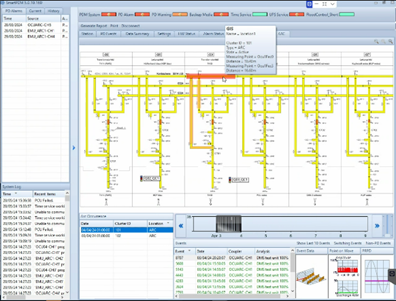

Arc detection is an advanced feature offered by Qualitrol’s PDMG-RH Gen3 System, designed to enhance the existing it’s PD monitoring capabilities. These features utilize the existing PD Monitoring System and UHF sensors and do not require any additional hardware. They allow users to remotely identify and record the location of arcs, greatly diminishing the need for manual investigation. By pinpointing the exact location of the arc, technicians can quickly reenergize healthy bays, saving valuable resources and reducing downtime.

Understanding Partial Discharge:

Partial discharge refers to localized electrical discharges that occur within insulation systems of high-voltage equipment. These discharges can be indicative of insulation degradation and the potential for equipment failure. Qualitrol’s PDM system, in conjunction with arc detection, has the capability to detect, and classify Partial Discharge by defect type, which serves as the foundation for risk assessment. With new advancements in technology and research, Qualitrol can offer the only UHF PD Monitoring system capable of identifying and locating arcs. This allows for the identification of the gas compartment where the arc occurred. By automatically identifying and locating arcs technicians can efficiently plan and execute appropriate actions to repair faults and ensure the integrity of the electrical grid.

The Benefits of Arc Detection and Localization:

Qualitrol’s arc detection and localization features offer numerous benefits, contributing to the safety and reliability of substation operations:

- Time and Cost Savings: By remotely identifying the location of flashovers, technicians can reenergize unaffected bays without the need for physical deployment to the site. This can save thousands of maintenance dollars per shift traditionally spent investigating arc location,

- Efficient Localization: The localization of arcs via the PDM system takes only about 20% of the time required for manual localization. This significant time reduction allows technicians to quickly respond to faults and expedite repairs, leading to substantial savings in terms of time and resources.

- Comprehensive Monitoring System: Qualitrol’s solution integrates multiple monitoring systems, including Partial Discharge Monitoring, Gas Density Monitoring, and Arc Detection, into a single GIS monitoring system. This comprehensive approach streamlines maintenance planning, simplifies training, and ensures more efficient operations.

- Enhanced Safety: By identifying and addressing potential faults and insulation degradation, arc detection and PD Monitoring contribute to the overall safety of substation operations and personnel. Timely repairs and maintenance reduce the risk of equipment failure and unplanned outages.

Conclusion:

Conclusion:

Arc detection and localization are crucial advancements in the field of Partial Discharge Monitoring. Qualitrol innovative solutions empower technicians to remotely identify and locate flashovers, saving time, reducing costs, and enhancing safety. By integrating arc detection and localization into a comprehensive monitoring system, Qualitrol ensures the reliability and efficiency of substation operations with these advancements, the electrical grid can continue to deliver uninterrupted electricity, supporting the needs of modern society.

Conclusion:

Conclusion: